Inside an Automated Ecommerce Warehouse: Integrating Technology for Seamless Operations

- David Nemec

- Nov 5, 2024

- 5 min read

As ecommerce continues to grow at a rapid pace, the demand for efficient, automated warehouses has surged. Modern ecommerce warehouses are becoming highly complex, relying on intricate systems of robotics, software, and intelligent devices to streamline operations. But behind the scenes, these systems require careful integration across multiple technology layers to achieve a seamless, automated workflow.

Here’s an inside look at the technology and layered architecture that make up a modern automated ecommerce warehouse.

1. Automated Storage and Retrieval Systems (AS/RS)

Automated storage and retrieval systems (AS/RS) are often the backbone of a modern warehouse. These systems are designed to efficiently store, manage, and retrieve products from designated storage areas. They can vary from robotic shuttles to vertical lift modules (VLMs) or carousel systems, all of which move items to and from storage locations without human intervention.

Each AS/RS solution is tailored to specific needs. For high-density storage, vertical carousels can maximize space by using vertical height. Robotic shuttle systems, on the other hand, provide rapid access to stored goods and often work well for inventory with high throughput requirements.

Integration Requirement: AS/RS must be connected with the overarching warehouse management system (WMS) and warehouse control system (WCS) to ensure real-time inventory updates and task prioritization.

2. Warehouse Control System (WCS)

The WCS is the orchestrator within the warehouse, coordinating all automated equipment in real time. It functions as the control layer that directs conveyors, sorting systems, and AS/RS based on instructions from the WMS. The WCS is also responsible for communicating with programmable logic controllers (PLCs) at the equipment level, sending signals to trigger specific actions or responses.

Integration Requirement: WCS acts as the critical link between the physical automation layer (PLCs and hardware controllers) and the WMS layer. It optimizes the routing, pacing, and movement of items, constantly making adjustments for peak efficiency.

3. Warehouse Management System (WMS)

The WMS is the brain of warehouse operations, managing everything from inventory tracking to order picking, packing, and shipping. Advanced WMS solutions provide real-time visibility into inventory levels, order status, and workforce management. They can handle complex tasks such as order batching, wave planning, and dynamic slotting to improve picking efficiency.

A key function of the WMS is the ability to integrate with enterprise resource planning (ERP) systems. This integration ensures that inventory data is constantly synchronized across the supply chain, enabling accurate forecasting, replenishment, and financial management.

Integration Requirement: The WMS needs seamless communication with both the WCS and ERP, acting as the central data hub. This enables it to manage workflows based on real-time inventory data, customer demand, and shipping requirements.

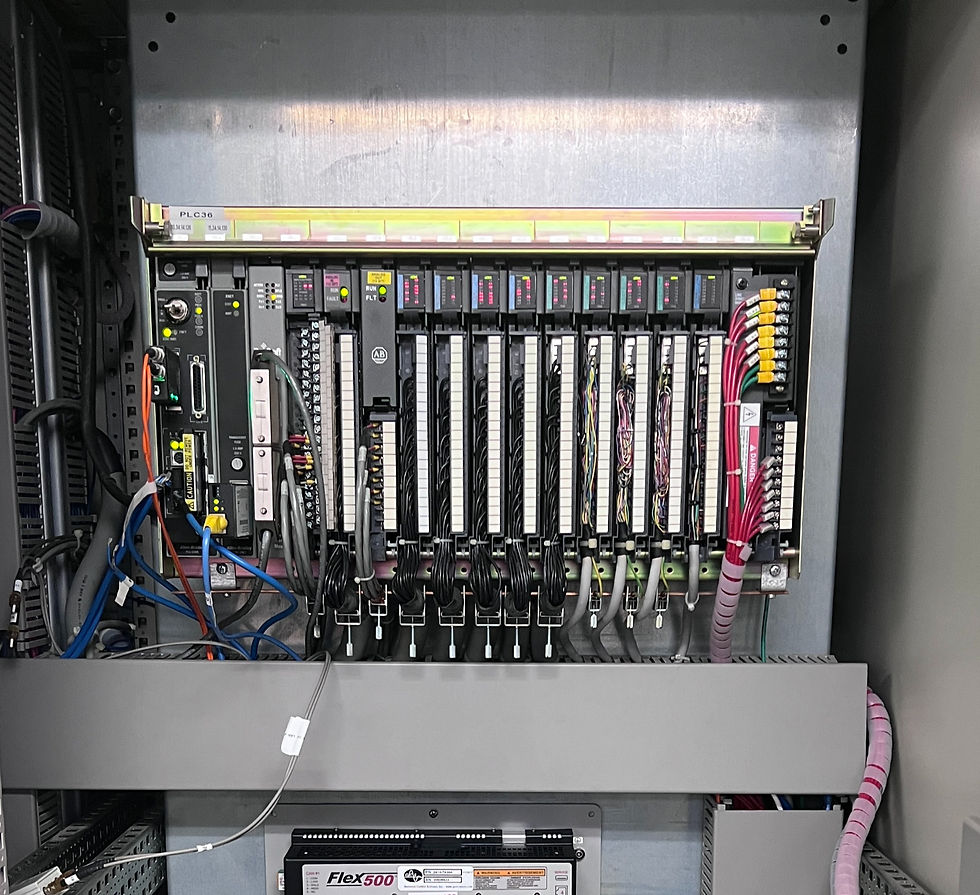

4. Programmable Logic Controllers (PLCs)

At the heart of the hardware layer, PLCs control specific actions within each piece of equipment, such as robotic arms, conveyors, and shuttles. They are responsible for executing specific tasks based on signals from the WCS. When an item needs to be moved along a conveyor, for instance, the WCS sends an instruction to the PLC, which triggers the movement.

PLCs operate on the factory floor, making quick, reliable decisions that ensure the equipment functions smoothly. They can also trigger emergency stops or safety actions if sensors detect an issue.

Integration Requirement: PLCs must have robust communication with the WCS to receive real-time operational commands and relay status updates, creating an efficient, tightly controlled automation loop.

5. Conveyor Systems and Sortation Technology

Conveyors are essential for moving items throughout the warehouse. Advanced conveyor systems often include integrated sortation technology to route items based on their next destination, such as packing stations or shipping zones. These systems are modular and scalable, allowing warehouses to adapt to changing volumes and product types.

Sortation systems can use barcode or RFID scanning to identify items and direct them to the correct path. When integrated effectively, sortation improves both speed and accuracy in high-volume order fulfillment.

Integration Requirement: Conveyor and sortation systems require direct integration with the WCS to ensure real-time decisions and routing are based on current order demands.

6. Automated Picking and Packing Solutions

Automated picking robots and packing stations add a significant boost to speed and accuracy in order fulfillment. Picking robots, for example, use advanced vision systems and machine learning algorithms to identify, grasp, and move items from storage to designated areas. Collaborative robots, or “cobots,” often work alongside human workers to handle repetitive tasks or support in areas with fluctuating demand.

Automated packing solutions can include systems that measure and pack items into appropriately sized boxes, optimizing space and reducing waste. These systems are often equipped with printing and labeling capabilities for efficient packaging and dispatch.

Integration Requirement: Picking and packing solutions need seamless WMS integration to prioritize and handle orders based on current demand, optimizing workflows without human intervention.

7. ERP System for End-to-End Supply Chain Management

An ERP system is essential for integrating warehouse data with broader business operations. It connects inventory, finance, sales, and procurement, allowing a real-time view of supply and demand. This integration enables accurate order forecasting, efficient inventory replenishment, and streamlined shipping processes.

Integration Requirement: ERP integration with the WMS ensures accurate tracking and forecasting, feeding data from the warehouse to inform decision-making across the business.

Bringing It All Together: A Layered System Architecture

To support smooth operations, an ecommerce warehouse must operate on a layered architecture. Here’s how the layers work together:

Edge Layer (Hardware): Includes PLCs, robotic systems, and sensors at the control level, directly handling the movement and monitoring of physical items.

Control Layer: The WCS communicates with PLCs and other edge devices to control the flow of goods and prioritize tasks in real time.

Data and Management Layer: The WMS integrates with the WCS to make higher-level decisions about order processing, inventory management, and task allocation.

Enterprise Layer: The ERP system integrates with the WMS for data-sharing across all departments, enabling real-time synchronization of inventory, orders, and finance.

Analytics and Optimization Layer: Modern warehouses incorporate AI-driven analytics tools to optimize workflows, predict maintenance needs, and improve efficiency over time.

This multi-layered approach provides the foundation for a robust, flexible, and highly responsive automated warehouse. As technology continues to evolve, automation solutions are becoming even more sophisticated, making it possible to build warehouses that are fully autonomous and capable of responding dynamically to shifts in demand.

Conclusion

Designing an automated ecommerce warehouse requires a holistic approach to technology, spanning hardware, software, and data management. Integrating these components into a cohesive system can create a streamlined, highly efficient warehouse environment, capable of handling the demands of today’s fast-paced ecommerce industry. Through proper integration, these systems not only enhance productivity but also offer the scalability and adaptability needed to thrive in an ever-evolving market. To get the first-hand experience from inside an automated warehouse and integrating technologies, reach out to Dokoma as a potential partner.

Comments